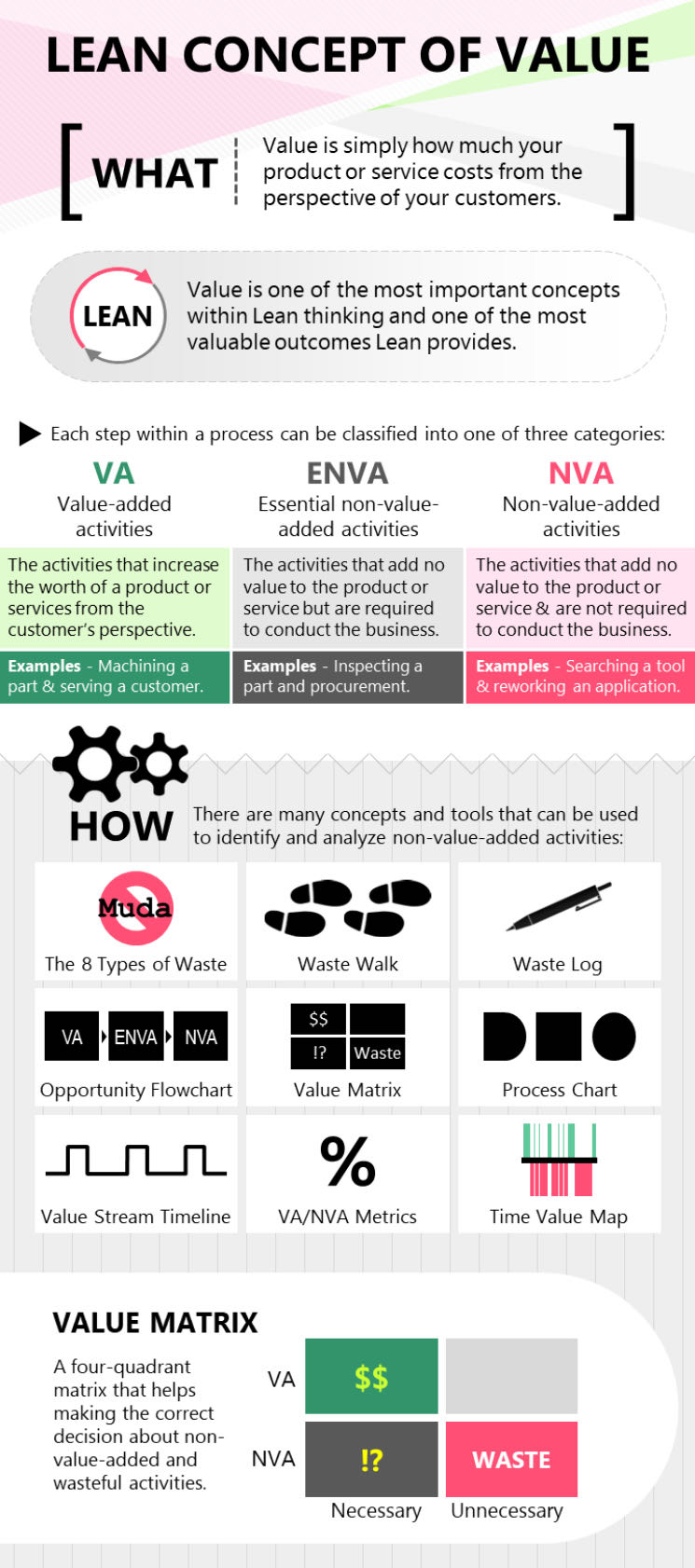

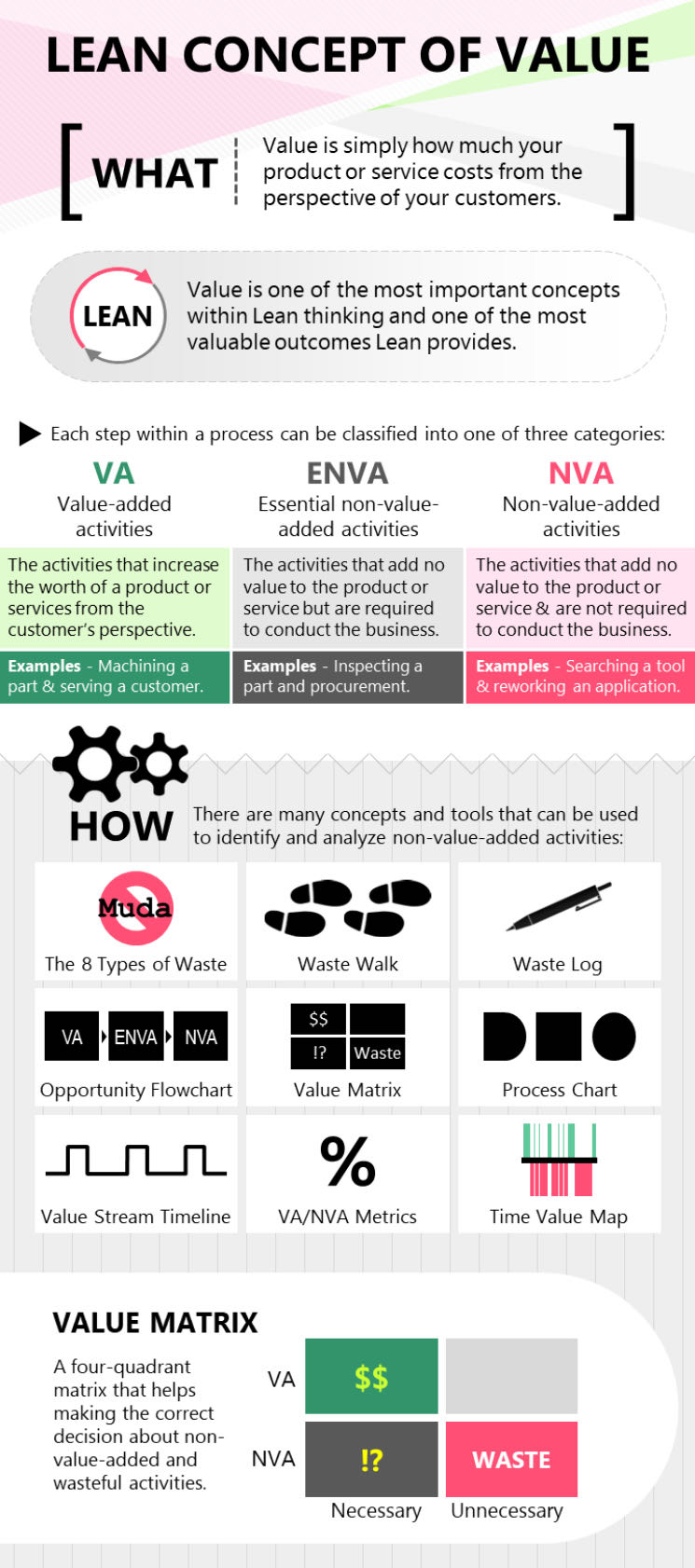

本图说明了业务或生产流程中的精益价值概念。精益是一种在不牺牲生产效率的前提下尽量减少浪费的系统方法。

【WHAT】它是什么?

该图从客户的角度定义价值,即客户愿意为产品或服务支付多少费用。它确定了任何业务流程中的三类活动:

1. 增值(VA):从客户角度直接提高产品或服务价值的活动。

2. 基本非增值(ENVA):不直接增加产品价值,但企业运作所需的必要活动。

3. 非增值(NVA):不增值且非企业所必需的活动。

【Why】为何重要?

了解这些类别有助于组织识别和消除浪费,提高效率,并关注客户的价值。从而提高客户满意度,降低成本,提高盈利能力。

【How】如何做?

图中列出了分析活动的工具和概念,如 Muda(8 种浪费类型)、Waste Walk 和 Waste Log,它们有助于识别和消除 NVA 活动。价值矩阵是对这些活动进行决策的工具,可将其分为必要或不必要。

【价值矩阵】:

这是一个象限,有助于就非增值和浪费活动做出决策。它将增值活动和非增值活动与必要或不必要的分类相互参照,有助于确定优先次序和消除这些活动。

给教练的教练问题:

给教练的教练问题:

- "您如何应用精益的价值概念来识别并最大限度地减少流程中的浪费,您预计这会对客户满意度和底线产生什么影响?

- "纵观您当前的流程,您能否找出一个不增值活动的具体例子,以及您将采取哪些措施来减少或消除这种活动?

- "利用价值矩阵,您将如何确定哪些必要的非增值活动可以优化以提高效率?

这些辅导问题鼓励领导者从客户的角度出发,批判性地分析他们的流程,找出效率低下的环节,并做出明智的决策来提升价值。

|

This diagram illustrates the Lean concept of value in a business or production process. Lean is a systematic method for waste minimization without sacrificing productivity.

What it is:

The diagram defines value from the customer’s perspective—how much they are willing to pay for a product or service. It identifies three categories of activities in any business process:

1. Value-Added (VA): Activities that directly increase the worth of a product or service from the customer’s viewpoint.

2. Essential Non-Value-Added (ENVA): Necessary activities that do not add direct value to the product but are required for the business to function.

3. Non-Value-Added (NVA): Activities that do not add value and are not necessary for the business.

Why it is important:

Understanding these categories helps organizations identify and eliminate waste, improve efficiency, and focus on what the customer values. This leads to better customer satisfaction, reduced costs, and improved profitability.

The How:

The diagram lists tools and concepts to analyze activities, such as Muda (the 8 types of waste), Waste Walk, and Waste Log, which help in identifying and eliminating NVA activities. The Value Matrix is a tool for decision-making regarding these activities, classifying them as necessary or unnecessary.

Value Matrix:

It’s a quadrant that helps in decision-making about non-value-added and wasteful activities. It cross-references the VA and NVA activities with a necessary or unnecessary classification, aiding in prioritization and elimination.

Coaching Question for Coaches:

• “How can you apply the Lean concept of value to identify and minimize waste in your processes, and what impact do you foresee this having on your customer satisfaction and bottom line?”

• “Looking at your current processes, can you identify a specific example of a non-value-added activity, and what steps will you take to reduce or eliminate it?”

• “Using the Value Matrix, how will you determine which necessary non-value-added activities can be optimized for greater efficiency?”

These coaching questions encourage leaders to critically analyze their processes, identify inefficiencies, and make informed decisions to enhance value from their customers’ perspective.

|

给教练的教练问题:

给教练的教练问题: